Human Machine Interaction

Hestia Technology Limited

2025

At Hestia Technology Limited, my work, as a lead designer and primarily as a product designer, was to solve and improve the user experiences between humans and complex, semi-automated machine operations. This work involved understanding how kitchen workers moved within the kitchen, operated traditional kitchen equipment, and understood digital user interfaces.

This project included conducting user research, creating user personas, and designing user interfaces to facilitate physical interactive user experiences with industrial machines.

Understanding The Machine

Disclaimer: Due to a NDA, not all details of the machine can be publicly revealed. All information provided therefore are publicly available and legally complaint. All additional functionalities of the machine can be found in https:///hestia.kitchen/tutorials

The Multicooker 6 is the latest generation of Multicooker machines created by Hestia. It features automatic food dispensing and cooking, aided by our latest SyncKitchen SAAS platform for directing machine steps for a controlled, consistent cooking output. This machine was designed to increase kitchen output pace by automating the cooking process, and reduce the need for qualified chefs/cooks at a time when restaurant workers are increasingly expensive, and difficult to hire. The interface was designed to accommodate a range of users with different kitchen knowledge and cooking ability, allowing chefs to create customized recipes, and utilize unskilled laborers to handle the rest.

Conducting User Research

At Hestia Technology Limited, my work, as a lead designer and primarily as a product designer, was to solve and improve the user experiences between humans and complex, semi-automated machine operations. This work involved understanding how kitchen workers moved within the kitchen, operated traditional kitchen equipment, and understood digital user interfaces.

This project included conducting user research, creating user personas, and designing user interfaces to facilitate physical interactive user experiences with industrial machines.

Disclaimer: Machine design not finalized at this stage of the video presented.

Developing User Personas

As part of our research to create a design system that catered to users of our machines, I developed a set of user personas through interviews and observations within different kitchen spaces which had Hestia products in use. Working with our customer success team, we measured their behaviors, and continuously interviewed them for pain points they had throughout the course of 6 months, listing down reoccurring issues to find the greatest, consistent weaknesses they had. Below are a few interviewees we worked with as a sample list of user personas.

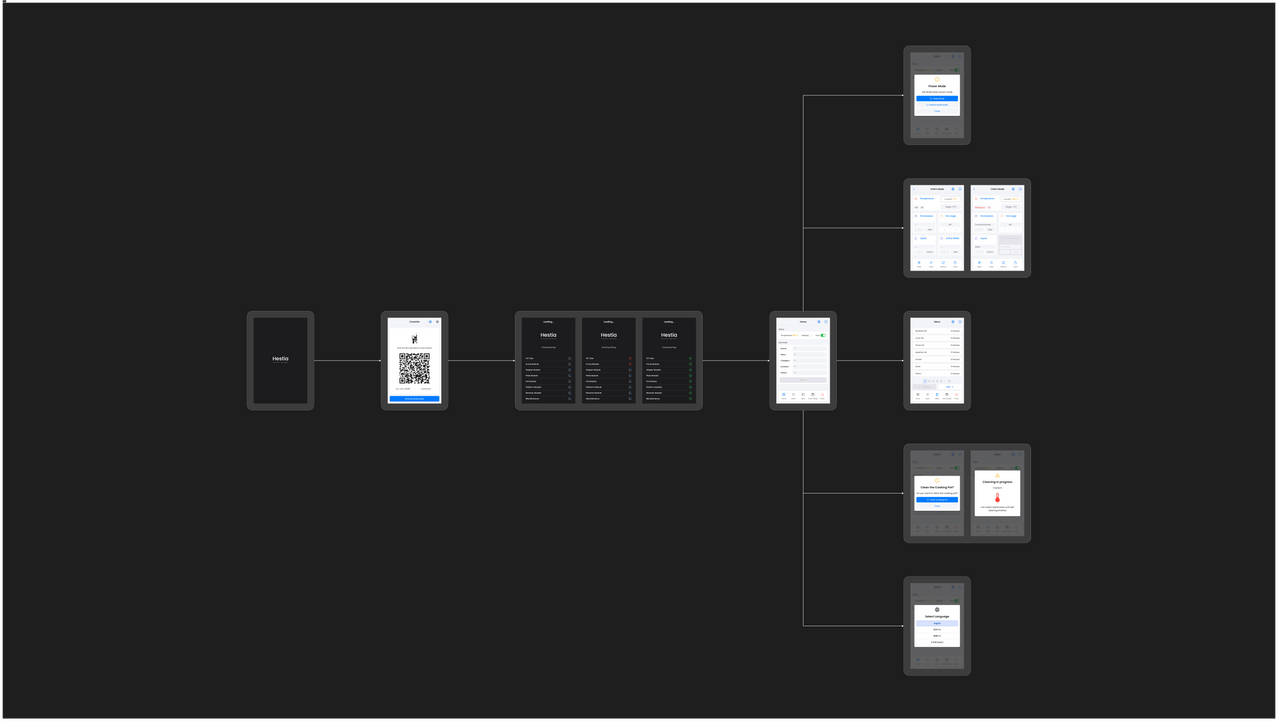

Interaction Flow System

To collect sauces without using the autonomous functions, users can disable the Auto Accept button, and enter the Menu. While the rest of the interface is unable to use scrolling or swiping features, a custom built-in script into the software used allowed our team to create a scrollable menu UI. With this feature available, we were able to create an intuitive selection process that users could perform to select and confirm the intended sauce to prepare. While the auto-accept function disables the POS ordering system and conveyor belt from linking with the machine, users could still take advantage of the autonomous motions of the machine to prepare an accurate portion and mixture of sauces needed.

Disclaimer: Labels are intentionally removed for specific UX identification purposes. Some details are withheld to prevent theft.

Function 1 - Home Page

Before opening up the home page, an initializer sequence is added to ensure all internal motors are homed and set to a predefined position. A checklist is added to allow new workers and others to scan a QR code which brings them to an external tutorial website, created and maintained by our design, and technical writing team.

The home page consists of a status bar which contains a temperature indicator, a heating on/off status, and an auto-delivery toggle. Users can also access a quick language swap to allow users from different language backgrounds to work together efficiently.

For greater efficiency, a bottom taskbar is included to allow users to toggle between different quick actions. This feature accommodated requests from chefs, and food scientists, who wanted to access the Chef's Mode function with less steps, and allow less experienced workers to power off the machine during closing hours.

Function 2 - Menu Selection

To reflect menu sortation in traditional Asian restaurant, the menu is sorted into Menu Set > Category > Recipe. This allows users to assign a category tag to a recipe. Because some of the same recipes tend to appear in multiple menu sets throughout the day, by assigning these tags, and assigning recipes into multiple different menus, the system can automatically sort recipes, which allow less experienced workers to understand which recipe to select based on time of availability instead of sorting through a mass of recipes, which can be in large quantities - something highly common in Chinese/Cantonese cuisine in particular.

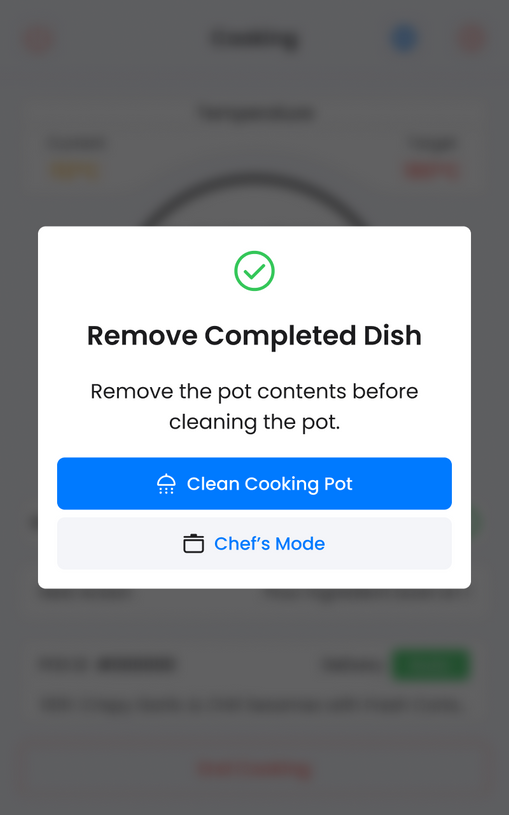

Function 3 - Cooking Process

To simulate a similar cooking experience, I divided the cooking process into 2 steps, a Preparation stage, and a Cooking stage - language familiar with cooks. The preparation stage allows users to monitor the ingredients required, either for manual preparation or automated preparation. Users can inspect the ingredient name, or SKU (Stock Keeping Unit) to locate and ensure the correct ingredients are placed.

To accommodate users who are busy working on multiple positions in the kitchen, the visual design of the cooking page is given a drastic, independent visual identity to highlight the stage. While status, step, and total time indicators are provided, we found that most users do not require reading each individual indicator especially working at a fast pace environment. Instead, the design provides a large clock with a timer showing the time left of the current stage.

When the dish is completed, a unique animation plays which replicates the timing and sequence of the machine's actions to reinforce the idea that cooking is complete and show new users that this step is performing as normal.

Function 4 - Language Requirements

Working with sales and customer success teams, we found that kitchen crews in the United States, Japan, Hong Kong, not only used different languages, but had crews which simultaneously spoke, or understood more clearly in different languages. For example, one restaurant in Brooklyn, NYC employed a mix of ethnically Black Americans, Chinese Americans, and Mexican Americans, who required English, Traditional Chinese, and Spanish. Another example in Akasaka, Tokyo employed Chinese and Japanese workers who worked at the same time. To reduce confusion and allow for fast paced simultaneous work, a language toggle button is included across all areas of the UI to ensure language switching was readily accessible.

Function 5 - Quick Access Tools/App Center

To accommodate additional functions, such as settings, and cleaning procedures, power mode, etc an App center was added to various areas of the interface. To prevent users from accessing functions that would cause issues with the mechanical and software logic, I designed different App Center interfaces to provide, and remove certain functions depending on what the user was doing with the Multicooker.

Function 6 - Settings

To accommodate a variety of functions and procedures, I designed a sorted page based on function differences. This system allows our team to ideate and implement additional settings and procedural requirements without running out of space within the page, something that was vital due to the nature of the interface which prevented scrolling or swiping functions.

Not all settings UI screens are shown here.

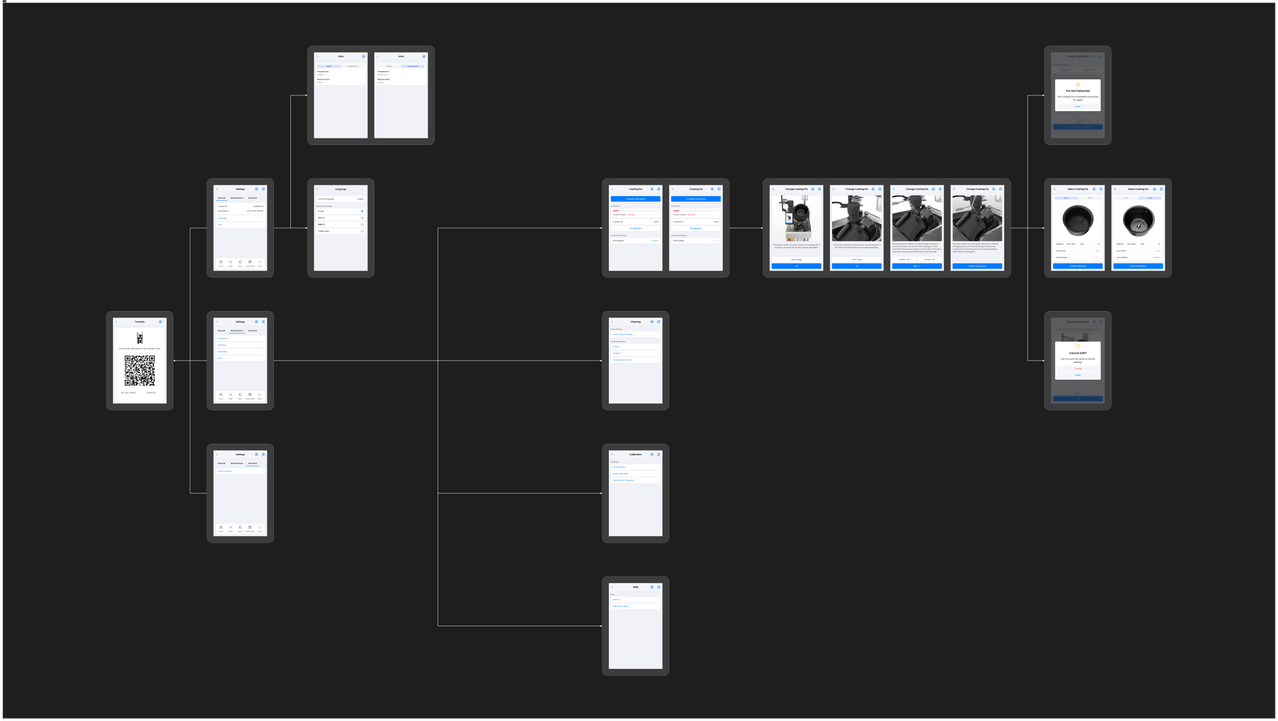

Function 7 - Changing Cooking Pots

As a blend of physical interaction and UI interaction, the challenge for this was to design a procedure to swap the cooking pot once it was used to a certain point. A status indicator is added to determine the current condition of the pot; this let us count one unit down every time the machine receives an order. An "Active Blade" status was also included at the front page to let users know if the "blade" or "spatula" at the center of the pot was individually active, or connected to the pot.

Once the user selects "Change Cooking Pot" a set of animations and images were prepared to show what to do with the machine, as well as what tools were necessary to change the pot. When the pot has been removed and replaced with a new pot, the user can toggle between "Pot A" and "Pot B" depending on the type installed. Alternatively, the user can select "Pot Selection" to change the pot without going through the changing process, to accommodate mistakes.

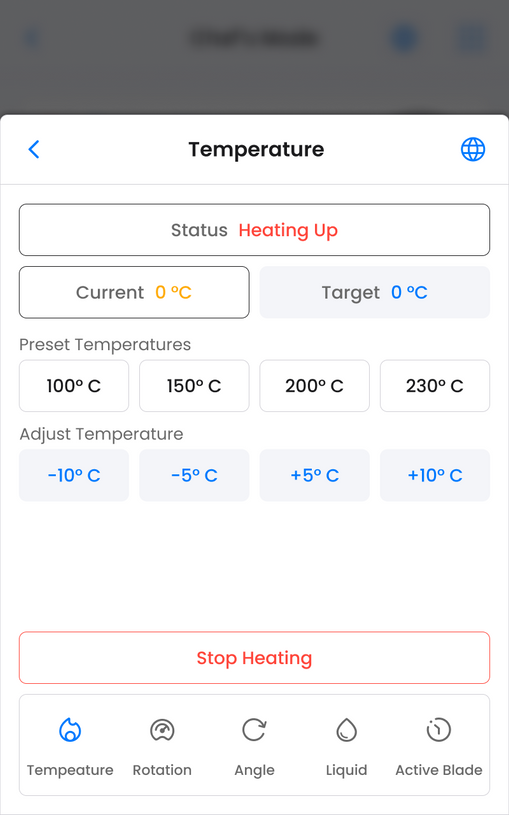

Function 8 - Chef's Mode - Custom Cooking and Machine Operations

Chef's Mode is a function created that allowed users to test and create recipes, and manually cook using the Multicooker. The challenge for this function was to include all interactive components with the machine so users could have a smooth, interactive experience that reflect all available customization options in SyncKitchen.

The first challenge was to utilize the platform function, which allowed users to set ingredients onto the Multicooker first, and utilize the platform system to automatically dispense the ingredients. This was initially done by hand using a timer, which required 2 people to perform. After working with food scientists on this issue, I designed an interface which allowed them to set the speed, shake count, and select which platform to activate. By doing so, we could replicate the exact timing that was naturally performed by the automated steps, reducing human error, and reducing the amount of people needed to use Chef's Mode for testing needs.

The second challenge was to allow users to quickly swap between functions in Chef's Mode, namely the "Active Blade", "Temperature", "Pot Rotation", "Pot Angle" and "Liquid" functions. To solve this, I utilized the same bottom taskbar design that is seen in the Home page. This similarity in design language not only helped users understand the functionality of this taskbar, but allowed users to immediate toggle between these difference functions, increasing the speed users could perform each step, reducing human delay and error.

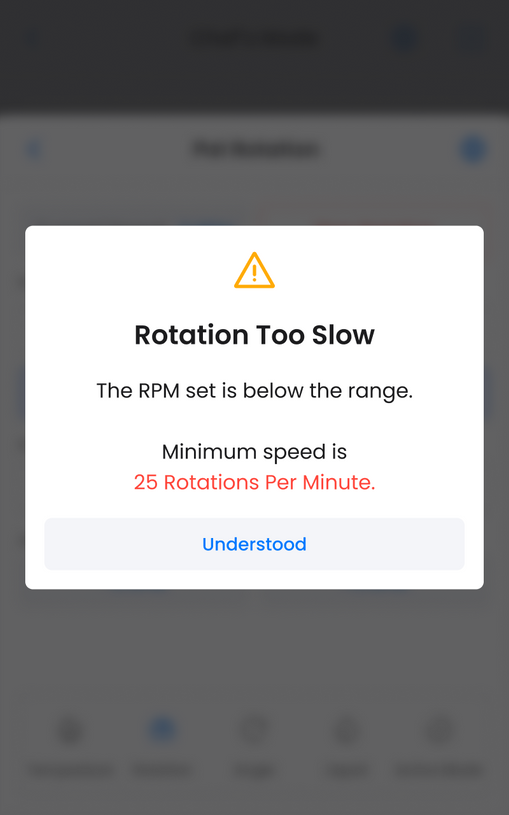

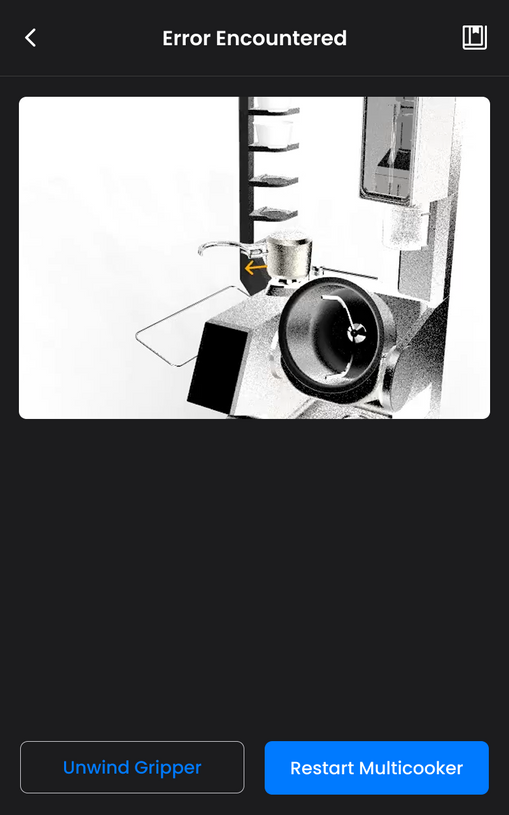

Function 9 - Machine Errors

At times, the machine may encounter some mechanical errors or shut down on purpose due to human negligence, such as forgetting to clean sensors, improper pot installation, and allowing sticky residue to jam moving components. To accommodate these issues, a set of error pages were designed that not only informed users what happened, but also guided them to addressing these issues promptly. Working with our clients and multiple kitchen crews, custom icons were also created to help users differentiate easily what each issue was, and animations were included to help with the guidance (we found that words were too complex for older users as they are unfamiliar with modern machine operations).

Function 10 - Factory Settings

Disclaimer: Due to sensitive information regarding factory settings, no images of the interface are provided. However, the user interface follows the same design principles, ensuring the user experience of our technicians across machines remain the same.